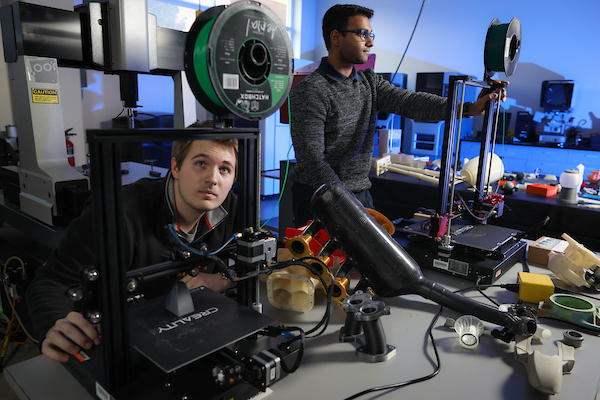

Mechanical Engineering Technology

Learn More About Mechanical Engineering Technology

Admission Requirements

None.

This program does not have specific admission requirements. Only admission to Kennesaw State University is required to declare this major.

General Education Core IMPACTS Curriculum Recommendations for this Major

M: Students should take MATH 1113 or higher.

T: Students should take MATH 1190 or higher.

T: Students should take PHYS 2211/L and PHYS 2212/L.*

* PHYS 1111/PHYS 1111L and PHYS 1112/PHYS 1112L may be substituted for PHYS 2211/PHYS 2211L and PHYS 2212/PHYS 2212L.

Concentrations Available

- General Concentration

- Energy-HVAC Concentration

- Engineering Graphics Design Concentration

- Manufacturing Concentration

Related Minors or Certificates Available

- Energy/HVAC Minor

- Engineering Design Graphics Minor

- Manufacturing Engineering Technology Minor

Sample Classes

-

MET 3331: Tool DesignJigs and fixtures for production machining processes are covered. Specific subjects include methods of gauging work pieces, ease and simplicity of operation, assembly methods, capital evaluation, techniques for locating and holding work pieces, time studies, tool steels, bending allowances, and reverse engineering techniques. The course is design project oriented. Projects include calculations of tooling forces and costs as well as complete production drawings of the tool design.

-

MET 4142: Mechanical Systems DesignFundamental rules, laws and criteria for using Finite Element Analysis (FEA) in the design of mechanical components and systems for structural integrity, reliability, and economy are covered, including energy methods, finite difference methods and numerical methods. Failure theory from static and variable loading is emphasized. Broad design issues such as design engineering economics, engineering ethics in design and intellectual property are covered. The course includes design projects using FEA.

-

MET 4411: RefrigerationThe theory and applications of commercial refrigeration systems are studied. The thermodynamic analysis of the refrigeration cycle, load calculations and selection of components for refrigeration systems are covered.

-

MET 4501: Machine DesignThe design of machines and machine elements, and cost considerations. The course focuses on power transmission in machines including gears, belts, pulleys, bearings, lubrication, clutches, brakes, chains, power screws, and gear trains. Stress calculations and material selection are discussed. Broad design issues such as safety, ethics, patents, product liability, time value of money, return on investment, and break even analysis are covered. Students start design teams for the capstone senior design project.